In food and oil production lines, cleanliness is not only a matter of hygiene, but also a key factor in maintaining consistent equipment performance. During continuous operation, oils and residues accumulate on surfaces and critical points, affecting both functionality and the overall appearance of the facility.

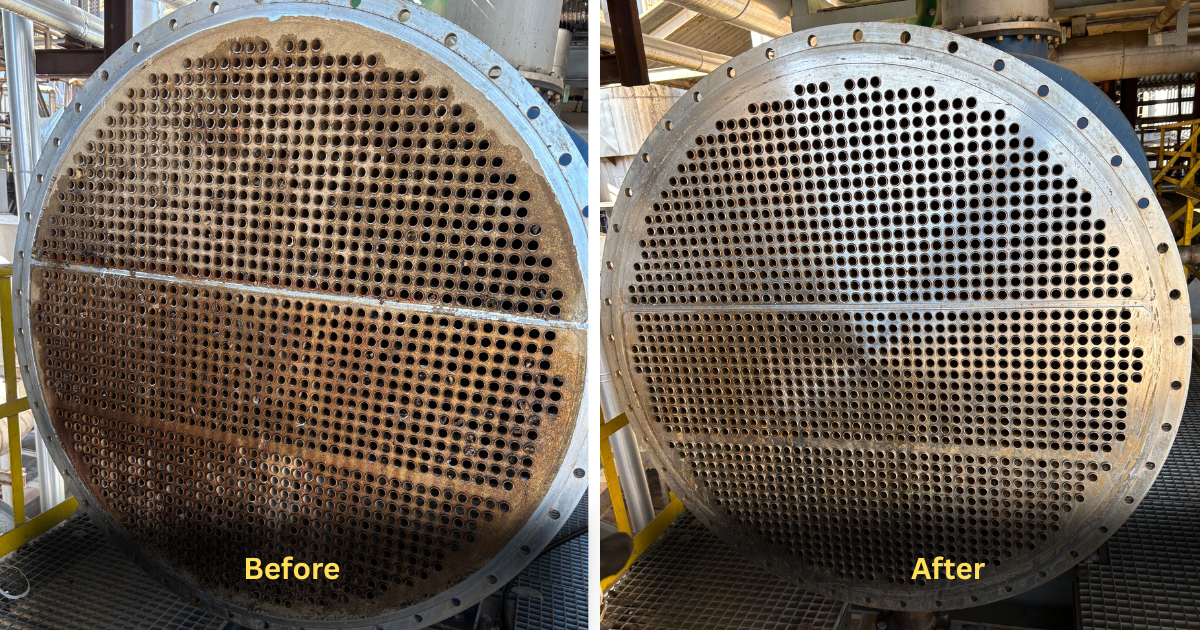

The difference before and after a properly executed industrial cleaning is often immediately visible. Deposits that, over time, create obstructions or reduce performance are removed, allowing the equipment to operate again under more controlled and stable conditions.

In the food and oil industry, requirements are particularly high. Industrial cleaning must be carried out in a targeted manner, without damaging materials and without disrupting production processes. For this reason, specialized methods such as high-pressure water jetting are used, enabling the effective removal of residues even from hard-to-reach areas.

Proper industrial cleaning contributes to maintaining performance, reducing the accumulation of contaminants, and improving the overall operational condition of the production line. At the same time, it enhances the reliability of the facility and helps limit the need for unplanned interventions.

STEPE undertakes industrial cleaning projects for food and oil production lines with a professional approach, tailored to the specific requirements of each facility. Through proper planning and the use of appropriate methods, a clean, controlled, and operationally efficient production environment is ensured.